Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Latin America Challenge: How Filter Driers Tackle Acidity in High-Temperature, High-Humidity Environments?

Filter Driers actively absorb moisture and chemical contaminants. They prevent corrosive acids from forming in refrigeration and AC systems. These acids degrade system components. Filter driers maintain system longevity and efficiency. This proactive role is crucial in Latin America's challenging high-temperature and high-humidity climate. A Copper Filter Drier provides essential protection in these demanding environments.

Key Takeaways

- Latin America's hot and humid weather makes harmful acids form in cooling systems.

- These acids damage parts like compressors, coils, and valves, making systems fail faster.

- Filter driers remove moisture and clean out solid bits from cooling systems.

- Molecular Sieves in driers soak up water, and activated alumina cleans up acids.

- Copper filter driers are strong and do not rust, making them good for tough weather.

- Picking the right size and type of drier helps it work best and last longer.

- Checking and changing filter driers often saves money and keeps cooling systems running well.

The Acidity Threat: Latin America's Climate Impact on Refrigeration Systems

Latin America's climate presents significant challenges for refrigeration and air conditioning systems. High temperatures and pervasive humidity create an environment where system components face constant threats. These conditions accelerate the degradation of refrigerants and oils, leading to the formation of corrosive acids. These acids then attack vital parts of the system, compromising efficiency and lifespan.

How High Temperatures Accelerate Refrigerant Breakdown

High ambient temperatures are a primary driver of system degradation. They directly impact the chemical stability of refrigerants and the lubricating oils within the system.

Thermal Degradation of Refrigerants and Oils

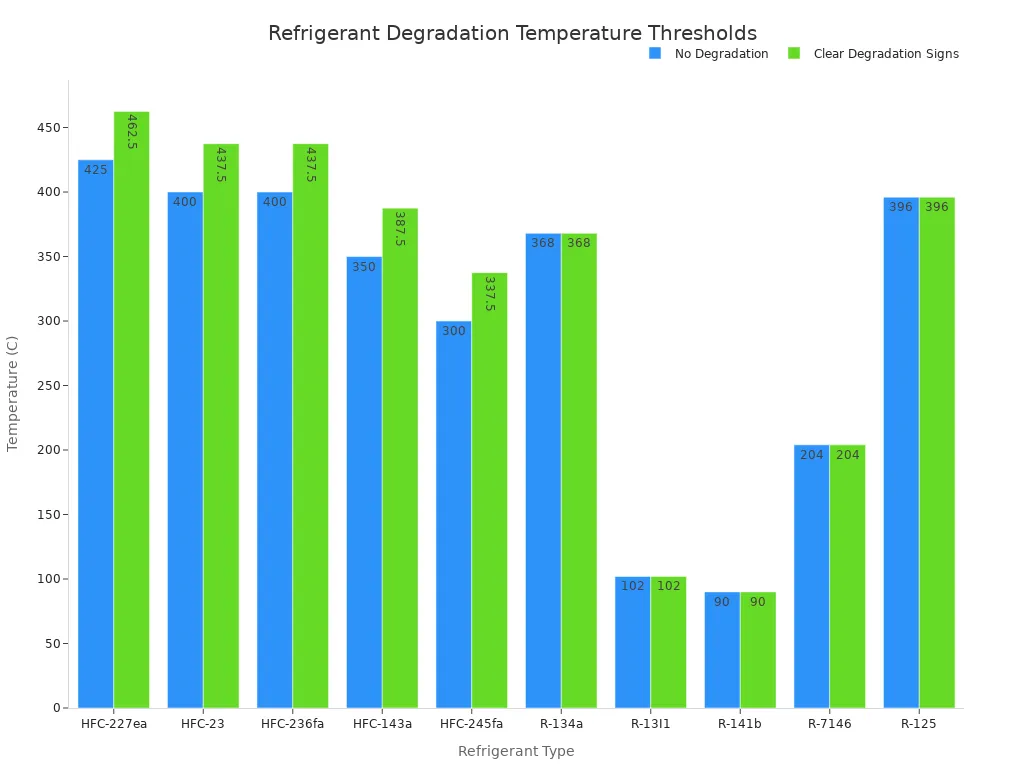

Elevated temperatures cause refrigerants and oils to break down more rapidly. This thermal degradation creates byproducts that contribute to acid formation. Overheating significantly accelerates refrigerant degradation, which reduces compressor efficiency and increases recovery times. Component degradation accelerates exponentially with temperature. For example, seals rated for 10,000 hours at normal temperatures may fail within 1,000 hours when consistently overheated. Different refrigerants also have varying temperature thresholds for degradation.

Increased Chemical Reaction Rates

Higher temperatures increase the kinetic energy of molecules. This leads to faster chemical reactions within the system. These accelerated reactions can quickly convert trace contaminants and moisture into harmful acids. The rate of acid formation increases significantly in warmer conditions.

The Role of High Humidity in Acid Formation

Humidity plays a critical role in the generation of acids within refrigeration systems. Moisture acts as a catalyst, initiating and sustaining corrosive chemical processes.

Moisture as a Catalyst for Acid Generation

Moisture is a key ingredient for acid formation. When moisture combines with refrigerants and oils, it creates a chemical reaction. This reaction produces various acids, including hydrochloric and hydrofluoric acids. These acids are highly corrosive and detrimental to system health.

Ingress Points for Atmospheric Moisture

In high-humidity environments, moisture can enter refrigeration systems through several pathways. Understanding these ingress points helps in preventing contamination.

- Room Design and Insulation Quality: Poor insulation, improperly sealed doors, frequently opened doors, and thermal bridges allow moisture-laden air to enter.

- Ambient Conditions: High external humidity and significant temperature differences between the cold room and its surroundings increase moisture load and condensation risk.

- Product Load and Type: Products like fresh produce, meat, and seafood release moisture, contributing to internal humidity.

- Air Exchange Rate: Frequent door openings and personnel traffic introduce moist warm air into the cold room.

- Condensation and Frost Control: Condensation on cold surfaces and frost accumulation on evaporator coils release moisture back into the air upon evaporation or defrosting.

- Ventilation System: Inadequate ventilation or systems that do not maintain positive pressure can allow moist external air to enter.

- Human Activity: Respiration and sweat from personnel inside the cold room add moisture.

Corrosive Effects of System Acids

Once formed, acids begin to attack the internal components of the refrigeration system. This corrosion leads to significant damage and system failure.

Hydrochloric and Hydrofluoric Acid Formation

Moisture in a refrigeration system mixes with refrigerant to form corrosive acids. These acids can erode the system's internal components, potentially causing leaks or complete system failure. This corrosion specifically damages the metal components of the system, leading to costly repairs. Moisture combines with refrigerants to create acids that corrode the metal components within the refrigeration system. This corrosion can result in leaks and system failures, necessitating expensive repairs and downtime.

Damage to Compressors, Coils, and Expansion Valves

The corrosive effects of these acids are widespread and severe.

- Hydrochloric and hydrofluoric acids, formed from moisture and halogenated refrigerants, are highly corrosive.

- Compressor motor windings in sealed units are among the first components to be affected.

- Valve reeds and seats corrode, potentially leading to breakage.

- Lubrication oil becomes contaminated, forming sludge and losing its lubricating properties, which impacts bearings and journals.

- Increased temperature accelerates these chemical reactions.

- Damage to discharge valve reeds and seats impairs compressor efficiency. This causes hot gas to leak back to the suction side and further increases compressor temperature, which in turn accelerates acid action.

- Prolonged operation under these conditions ultimately leads to complete compressor failure.

- The pungent smell from a burned-out sealed unit is attributed to hydrofluoric acid.

Filter Driers: Essential Components for Acid Prevention

Filter driers play a crucial role in protecting refrigeration and air conditioning systems. They actively remove harmful substances that degrade system performance and longevity. These components act as guardians, ensuring the refrigerant circuit remains clean and dry.

Primary Functions of a Filter Drier

Filter driers perform two critical functions: drying and filtering. They protect system components by capturing and adsorbing water particles and harmful solid substances. This prevents these contaminants from circulating and damaging compressors, valves, and sensors. Ultimately, filter driers maintain optimal system operation.

Moisture Absorption and Desiccation

Filter driers remove moisture from the refrigeration system. This drying function utilizes molecular sieves to adsorb moisture. Removing water prevents the formation of corrosive acids. It also stops ice from forming, which can block expansion valves and capillaries.

Solid Contaminant Filtration

Filter driers also filter the refrigerant, ensuring it remains free of impurities. This function involves removing debris, brazing chips, dust, rust, and sludges. These contaminants can reduce efficiency and lead to compressor failure. The filter drier uses fibrous media and glass wool layers to trap these impurities.

Desiccant Technologies for Acid Control

Filter driers employ specialized desiccant materials to combat moisture and acidity effectively. These materials have unique properties that target specific contaminants.

Molecular Sieves for Moisture Removal

Molecular sieves are crystalline aluminosilicates characterized by uniform pore sizes. They selectively adsorb molecules based on size and polarity. This makes them ideal for trapping moisture in refrigerant systems without altering the refrigerant's chemical properties. Molecular sieves possess a high capacity for water absorption due to their crystalline structure and uniform pore sizes. These sieves often have positive charges (cations) which attract polarized water molecules, effectively binding the moisture. This process keeps water levels low, preventing issues such as corrosion, freeze-ups, and acid formation. Specific types like XH 7 and XH 3 are commonly used for their moisture absorption capabilities. Their high water absorption capacity and chemical stability are crucial for preventing corrosion, enhancing thermal efficiency, and extending the lifespan of equipment in demanding refrigeration environments.

Activated Alumina for Acid Scavenging

Activated alumina specifically targets acids formed from moisture reacting with refrigerant or lubricant degradation. It absorbs these acids, neutralizing their corrosive effects. This acid-scavenging capability is vital for systems already contaminated or operating in conditions prone to acid formation. A robust Copper Filter Drier often incorporates activated alumina for enhanced acid protection.

The Importance of Physical Filtration

Beyond chemical absorption, physical filtration is equally important. It prevents solid particles from causing mechanical damage and contributing to chemical reactions.

Removing Particulates that Contribute to Acid Formation

Solid particulates, such as metal shavings or dirt, can act as catalysts for chemical reactions. They provide surfaces where moisture and refrigerants can react, accelerating acid formation. Physical filtration removes these particulates, reducing the potential for acid generation.

Preventing System Blockages and Wear

Physical filtration also prevents system blockages and wear. Fine particles can clog capillary tubes, expansion valves, and restrict refrigerant flow. Larger debris can cause abrasive wear on compressor components, leading to premature failure. Effective filtration protects these critical parts, ensuring smooth operation and extending system life.

Optimizing Filter Drier Selection for Latin American Conditions

Selecting the correct filter drier is paramount for system longevity and efficiency, especially in Latin America's challenging climate. Engineers must consider specific environmental factors and system requirements. Proper selection ensures maximum protection against moisture and acid contamination.

High Moisture Absorption Capacity for Humid Climates

Humid environments demand filter driers with superior moisture absorption capabilities. These components actively remove water from the refrigerant circuit. This action prevents the formation of corrosive acids and ice blockages.

Selecting Driers with Enhanced Desiccant Volume

Filter driers must effectively absorb and trap excess moisture. Their materials need moisture resistance to maintain effectiveness over time. A high moisture and contaminant removal capacity is crucial, especially in humid environments or systems prone to moisture ingress. This capacity is measured by the amount of moisture the drier can absorb. Selecting driers specifically designed for high absorption ensures long-lasting performance.

Matching Drier Capacity to Environmental Load

The size of the filter drier directly impacts its capacity. Larger filter driers generally offer greater capacity for moisture and contaminant removal. However, proper sizing is essential. Experts emphasize the critical importance of properly sizing the suction line dryer to align with the system's design refrigerant flow rate. Incorrect sizing can lead to significant operational issues. An oversized dryer, for instance, can reduce refrigerant flow velocity. This reduction potentially hinders oil return to the compressor and causes damage. Conversely, an undersized dryer creates an undesirable pressure drop on the compressor side. This results in lower suction pressure, increased compression ratios, and a less efficient HVACR system.

Acid-Scavenging Desiccants for Active Neutralization

Beyond moisture removal, filter driers must also address existing and potential acid contamination. Specialized desiccants play a vital role in this process.

Neutralizing Existing Acids in Contaminated Systems

Systems operating in high-temperature, high-humidity conditions often accumulate acids. Activated alumina, a common desiccant, excels at absorbing these acids. It neutralizes their corrosive effects. This capability is crucial for systems already contaminated or those experiencing refrigerant and oil breakdown. A Copper Filter Drier, when equipped with activated alumina, offers robust protection.

Preventing Future Acid Build-up

Proactive acid scavenging prevents future acid formation. By continuously removing trace acids and their precursors, these desiccants protect system components from ongoing corrosion. This action extends the lifespan of compressors, coils, and expansion valves. It also maintains system efficiency.

Sizing and Placement for Maximum Effectiveness

Optimal performance of a filter drier depends on its correct sizing and strategic placement within the refrigeration system. These factors ensure the drier can effectively process the refrigerant flow.

Strategic Positioning in High-Temperature Systems

Experts emphasize properly sizing the suction line dryer. It must align with the system's design refrigerant flow rate. System capacity, measured in tons, dictates drier size; larger systems require bigger filter driers to manage a greater volume of refrigerant. For instance, a 1-2 ton residential unit needs a smaller drier than a 10-ton commercial system. Refrigerant type also influences drier size. Different refrigerants have distinct properties affecting drier size. Some absorb more moisture, while others carry more contaminants. Operating conditions, such as high humidity or significant dust levels, necessitate a larger filter drier. A system in a hot, humid area or a dusty factory setting will require a more robust drier than one in a clean office environment.

Ensuring Optimal Refrigerant Flow and Contact Time

Manufacturers provide sizing charts as a starting point. These charts consider system capacity and refrigerant type. However, these are guidelines. Specific operating conditions might warrant selecting a larger drier than initially recommended. Incorrect sizing leads to operational issues. Proper placement ensures the refrigerant has sufficient contact time with the desiccant material. This maximizes the drier's ability to absorb moisture and acids. It also maintains optimal refrigerant flow without creating excessive pressure drops.

Copper Filter Drier: A Robust Solution for Challenging Environments

Refrigeration systems in demanding climates require components built for resilience. The Copper Filter Drier stands out as a robust solution. Its construction and design offer superior protection against common system threats like moisture and acidity. This type of drier ensures long-term system health and operational efficiency.

Advantages of Copper Construction

Copper is a preferred material in refrigeration for several reasons. Its inherent properties make it ideal for constructing durable and reliable filter driers.

Durability and Corrosion Resistance

Copper naturally resists corrosion. This property is crucial in environments where moisture and potential acid formation threaten system integrity. A Copper Filter Drier withstands harsh internal conditions, preventing material degradation. This durability ensures the drier maintains its structural integrity and protective functions over extended periods. It does not easily succumb to the corrosive effects of acids that can form within the refrigerant circuit.

Compatibility with Refrigeration Systems

Copper is highly compatible with common refrigerants and lubricating oils. This compatibility prevents adverse chemical reactions that could introduce new contaminants or degrade system performance. Its widespread use in refrigeration tubing and components means a Copper Filter Drier integrates seamlessly into existing systems. This ensures a reliable and leak-free connection, maintaining the system's hermetic seal.

Internal Design for Enhanced Performance

The effectiveness of a filter drier also depends on its internal engineering. Thoughtful design maximizes its ability to filter contaminants and absorb moisture.

Optimized Flow Paths for Efficient Filtration

Manufacturers engineer filter driers with optimized internal flow paths. These designs, combined with high-porosity desiccant beds, achieve a low pressure drop. This remains true even when systems operate under high load conditions. Different flow path designs exist to enhance filtration efficiency:

- Straight-through flow path: Refrigerant enters from one end and exits from the other. This design is simple to manufacture and offers a low pressure drop. However, it may not fully utilize the filtration media.

- Radial flow path: Refrigerant flows from the outer periphery towards the center. This design promotes a more uniform distribution of refrigerant across the filtration media, enhancing filtration efficiency. It can be more complex to manufacture and may result in a higher pressure drop.

Secure Desiccant Containment

The internal structure securely holds the desiccant material. This prevents desiccant migration or breakdown, which could lead to blockages or reduced effectiveness. A robust internal screen or mesh keeps the desiccant firmly in place. This ensures the refrigerant always passes through the active desiccant bed for maximum moisture and acid absorption.

Application in High-Temperature, High-Humidity Settings

The unique characteristics of a Copper Filter Drier make it exceptionally well-suited for challenging climates.

Reliability in Demanding Latin American Climates

Latin America's high temperatures and humidity create a demanding environment for refrigeration systems. The inherent durability and corrosion resistance of copper provide reliable protection. This makes the Copper Filter Drier a dependable choice for maintaining system performance and preventing premature failures in such conditions. It consistently performs its critical functions despite environmental stressors.

Contribution to System Longevity

By effectively removing moisture and acids, a copper filter drier directly contributes to the overall longevity of the refrigeration system. It protects vital components like compressors, coils, and expansion valves from corrosive damage. This proactive protection reduces the need for costly repairs and replacements. It ensures the system operates efficiently for many years.

Best Practices for Installation and Maintenance of Filter Driers

Proper installation and diligent maintenance of filter driers are crucial for their effectiveness. These practices ensure optimal system performance and longevity, especially in challenging environments. Technicians must follow specific guidelines to maximize the protective capabilities of these essential components.

Proper Installation Techniques

Correct installation prevents immediate and long-term issues. It ensures the filter drier functions as intended, protecting the refrigeration system from contaminants.

Ensuring Hermetic Seals and Connections

Achieving hermetic seals is paramount during filter drier installation. Technicians must prevent any moisture or air ingress.

- When installing a replaceable filter-drier core, use a torque wrench. Tighten bolts according to manufacturer specifications. Over-tightening can warp the aluminum flange and compromise the seal.

- To prevent overheating internal components during brazing, use a wet rag. Keep the drier cool with this method.

- Always cut out old driers instead of sweating them out. This prevents debris from entering the system.

- Adhere to directional flow arrows during installation. This ensures proper refrigerant flow through the desiccant.

Avoiding Contamination During Service

Preventing contamination during service is equally important. Technicians should work in a clean environment. They must use clean tools and materials. This minimizes the introduction of new moisture or particulates into the system.

Recommended Replacement Frequency

Regular replacement of filter driers is a critical maintenance practice. It ensures continuous protection against moisture and acid.

Monitoring System Performance for Drier Saturation

Monitoring system performance helps identify when a filter drier approaches saturation. This allows for timely replacement.

- Increasing Pressure Drops: This serves as an early warning indicator for the condition of the filter.

- Differential Pressure (ΔP): This is a critical indicator of filter health. Regularly log ΔP across each filter stage (weekly or bi-weekly). Replace elements when ΔP approaches or reaches the maximum recommended level.

- Pressure Dew Point (PDP): Periodically test the dew point at the dryer outlet or critical points using a calibrated hygrometer. Continuous monitoring is ideal for desiccant systems in critical applications. A rising PDP indicates issues such as saturated desiccant, a failing heater, or high inlet temperatures. Sensors can detect moisture levels or pressure drops. These sensors provide valuable data for system management. Modern filter driers can also integrate with system control units via APIs. This allows for remote monitoring and predictive maintenance. It helps identify clogging or moisture saturation early.

Proactive Replacement Schedules for Acid Protection

Establishing proactive replacement schedules is beneficial. This prevents the drier from becoming fully saturated. It ensures continuous acid protection, especially in high-stress environments. Manufacturers often provide guidelines for replacement intervals.

System Monitoring for Early Detection of Acidity

Early detection of acidity prevents extensive system damage. Various tools and techniques are available for this purpose.

Acid Test Kits and Oil Analysis

Acid test kits and oil analysis provide direct evidence of acid contamination.

- Port Testing (e.g., QwikCheck): These kits feature built-in core depressors and indicator paper. The paper changes color (e.g., yellow to orange or red) when exposed to acid in the refrigerant. They offer quick, simple results, ideal for residential and light commercial applications. They detect residual acid but not mild organic acids from POE oil breakdown directly in the oil. QwikCheck® indicator paper changes from golden yellow to pink or red with as little as 1 part per million (PPM) of acid. It provides a 2-second refrigeration acid test, indicating Pass/Fail, and works with all refrigerants and oils.

- Field Testing (e.g., Sporlan's Test-All): This method involves sampling oil and exposing it to a reagent. The reagent changes color in the presence of acid. It suits larger systems or when oil breakdown results from hydrolysis or high temperatures. This provides a better indication of acid in the oil itself. Technicians fill a vial with 2.5 cc of test oil and shake it vigorously. A blue/violet color indicates no acid, green means moderately acidic, and yellow signifies acidic conditions.

- Lab Testing: Submitting an oil sample to a laboratory provides comprehensive analysis. This reveals exact moisture and acid concentrations. It identifies particulates and measures oil viscosity. Lab testing is essential for mission-critical applications requiring a thorough breakdown of oil composition.

Pressure and Temperature Readings as Indicators

Abnormal pressure and temperature readings can indirectly indicate system issues, including potential acid formation. Unusually high discharge temperatures or low suction pressures might signal problems. These issues warrant further investigation, including acid testing.

Case Studies: Mitigating Acidity with Filter Driers in Latin America

Filter driers demonstrate their value through tangible results in Latin American refrigeration and AC systems. Real-world applications show how these components effectively combat acidity. They protect critical equipment and deliver significant operational advantages. These case studies highlight the practical benefits of proactive acid management.

Extending System Life and Reducing Maintenance Costs

Implementing filter driers leads directly to longer equipment lifespans and fewer repair incidents. This translates into substantial savings for businesses and operators.

Examples of Prolonged Equipment Lifespan

A large cold storage facility in Brazil faced frequent compressor failures due to acid contamination. After installing high-capacity filter driers with activated alumina, the facility observed a dramatic change. Compressor lifespan increased by over 40%. This reduced the need for premature replacements. Similarly, a supermarket chain in Mexico experienced consistent issues with expansion valve corrosion. The introduction of specialized filter driers significantly extended the operational life of these valves. This ensured consistent cooling performance.

Documented Reductions in Repair Incidents

A major food processing plant in Argentina documented a 60% reduction in unscheduled maintenance calls related to refrigeration system breakdowns. This occurred after they adopted a comprehensive filter drier replacement program. Before this, acid-related failures caused significant downtime. A hotel complex in the Caribbean also reported a 35% decrease in AC unit repairs. This improvement directly correlated with the regular replacement of filter driers. These components effectively removed moisture and neutralized acids.

Economic Benefits of Proactive Acid Management

Proactive acid management with filter driers offers clear economic advantages. It prevents costly failures and improves overall system efficiency.

Cost Savings from Preventing Compressor Failures

Compressor failures represent one of the most expensive repairs in refrigeration systems. A logistics company in Chile saved an estimated $50,000 annually across its fleet of refrigerated trucks. This saving resulted from preventing compressor burnouts through diligent filter drier usage. The cost of a new compressor, plus labor and lost revenue from downtime, far exceeds the investment in filter driers. Proactive measures safeguard these vital components.

Improved Energy Efficiency and Operational Uptime

Acid contamination degrades system efficiency. It causes components to work harder and consume more energy. A beverage manufacturer in Colombia noted a 10% improvement in energy efficiency for its chillers. This improvement followed the implementation of an optimized filter drier strategy. Clean systems operate more efficiently. This reduces electricity consumption. Furthermore, fewer breakdowns mean greater operational uptime. This ensures continuous production and prevents revenue losses. Businesses maintain consistent service delivery.

Filter driers are indispensable for combating acidity in refrigeration and AC systems operating in Latin America's high-temperature, high-humidity environments. They actively remove moisture and neutralize acids. This ensures system reliability and longevity, safeguarding critical components. Regular maintenance, correct selection, and proper installation are paramount to their effectiveness in these challenging conditions. These practices protect equipment and optimize performance.

FAQ

What causes acidity in refrigeration systems in Latin America?

High temperatures and humidity accelerate refrigerant and oil breakdown. This process creates corrosive acids. Moisture acts as a catalyst, combining with refrigerants to form hydrochloric and hydrofluoric acids. These acids then damage system components.

How do high temperatures contribute to system degradation?

High temperatures accelerate the thermal degradation of refrigerants and oils. This increases chemical reaction rates within the system. Faster reactions convert trace contaminants and moisture into harmful acids more quickly. This leads to increased corrosion and component wear.

What is the primary role of a filter drier?

A filter drier performs two main functions. It absorbs moisture from the refrigerant to prevent acid formation and ice blockages. It also filters solid contaminants like debris and metal shavings. This protects compressors and other vital components from damage.

How do molecular sieves and activated alumina differ in function?

Molecular sieves primarily remove moisture from the system. They trap water molecules based on size and polarity. Activated alumina specifically scavenges and neutralizes acids. It absorbs acids formed from refrigerant or lubricant degradation, protecting against corrosion.

Why is copper a good material for filter driers in challenging climates?

Copper offers excellent durability and natural corrosion resistance. This protects the drier from internal acids and external environmental factors. Copper is also highly compatible with common refrigerants and oils. This ensures seamless integration and reliable performance in demanding conditions.

How often should one replace a filter drier?

Replacement frequency depends on system conditions and manufacturer guidelines. Technicians should monitor system performance for signs of drier saturation, such as increased pressure drops. Proactive replacement schedules are crucial, especially in high-humidity or contaminated environments, to ensure continuous protection.

What are the signs of acid contamination in a system?

Signs of acid contamination include unusual pressure and temperature readings. Technicians can use acid test kits or perform oil analysis for direct detection. A pungent smell from a burned-out compressor also indicates hydrofluoric acid presence. Early detection prevents extensive system damage.