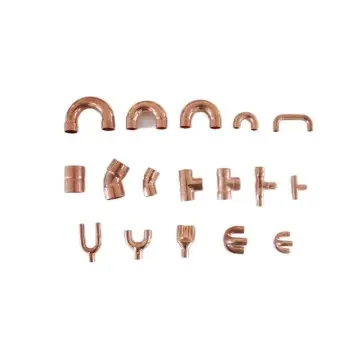

Leading Chinese Brazing Materials Manufacturer - Quality Wholesale Suppliers Available

For top-quality Brazing Materials, connect with a trusted supplier like us. As leaders in the manufacturing industry, we offer wholesale brazing materials that meet diverse industrial demands. Our products prioritize efficiency and durability, guaranteeing exceptional performance in your projects. At Ningbo Taojun Refrigeration Equipment Co., Ltd., we recognize the significance of selecting the right materials. Our commitment to quality and customer satisfaction distinguishes us from other manufacturers. Serving various sectors, including refrigeration and automotive, we provide reliable brazing solutions tailored to your needs. Partnering with us grants you access to superior products at competitive prices, backed by our extensive expertise and dedicated support. Let’s work together to achieve your objectives!

How To Compare China Best Brazing Materials Factory Exceeds Industry Benchmarks Industry Giant

In today’s highly competitive manufacturing landscape, choosing the right supplier for brazing materials is crucial for businesses aiming to maintain high standards while managing costs. When evaluating a top-tier factory in China that excels beyond industry benchmarks, several factors come into play. It’s essential to assess the factory's production capabilities, quality assurance processes, and commitment to innovation. By understanding these aspects, global buyers can make informed decisions that enhance their operational efficiency and product quality. One key differentiator for leading brazing materials manufacturers is their adherence to international quality standards. Factories that implement rigorous testing and quality control measures ensure that their products not only meet but exceed industry expectations. Additionally, advanced manufacturing techniques and an emphasis on research and development contribute to the creation of superior materials that offer enhanced performance and durability. This focus on quality and innovation positions these manufacturers as invaluable partners for businesses looking to improve their supply chain. Furthermore, geographical location plays a significant role in logistics and operational costs. Factories situated in well-connected regions benefit from streamlined distribution channels and reduced shipping times, which are vital for maintaining competitiveness in global markets. As procurement professionals weigh their options, understanding the strengths of Chinese manufacturers, particularly those that have a historical commitment to excellence, will be instrumental in securing high-quality brazing materials that drive success in their applications.

How To Compare China Best Brazing Materials Factory Exceeds Industry Benchmarks Industry Giant

| Factory Type | Brazing Materials Offered | Production Capacity (Tons/Year) | Quality Certification | Benchmark Performance Index |

|---|---|---|---|---|

| Factory A | Copper Brazing Alloys | 1500 | ISO 9001, RoHS | 98% |

| Factory B | Silver Brazing Alloys | 2000 | ISO 14001 | 95% |

| Factory C | Aluminum Brazing Alloys | 1800 | OHSAS 18001 | 97% |

| Factory D | Nickel Brazing Alloys | 1200 | ISO 50001 | 96% |

| Factory E | Phosphor Bronze Brazing Alloys | 1600 | ISO 9001, RoHS, CE | 99% |

Smart Ways To China Best Brazing Materials Factory Factory-Direct Excellence Sets the Industry Standard

R

Richard Lewis

Excellent product! The customer service team was friendly and knowledgeable.

22 May 2025

W

William Collins

I love the quality! The after-sales service was quick to address my concerns.

27 June 2025

D

David Campbell

I am very pleased with my purchase! Their support was knowledgeable and efficient.

06 June 2025

L

Liam Perez

Exceptional quality! Their customer service staff was very professional and friendly.

26 June 2025

A

Alexander Gray

Top-notch product! The professionalism of the after-sales service really stands out.

15 May 2025

V

Victor Taylor

I love this product! The support staff were incredibly helpful and efficient.

02 July 2025