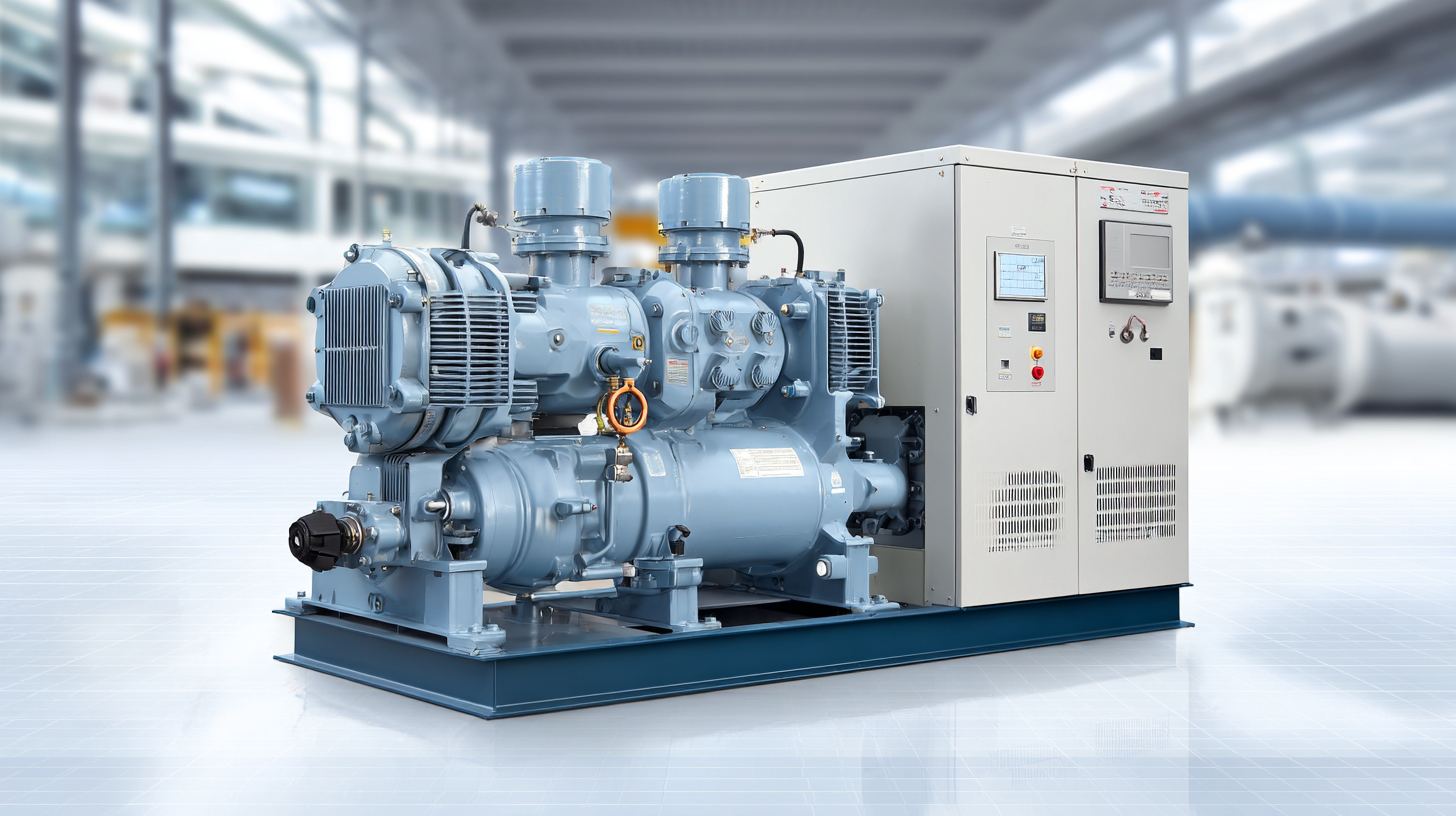

In the realm of modern industrial applications, the efficiency of compressors is crucial for achieving optimal operational performance. Among the various components that contribute to compressor efficiency, the "Filter Dryer For Compressor" stands out as an essential element. This technology not only aids in the effective removal of moisture and contaminants from compressed air systems but also plays a pivotal role in safeguarding the internal mechanisms of compressors. By optimizing the air quality, filter dryers enhance the longevity and reliability of compressors, enabling them to function at peak capacity. In this guide, we will explore practical tips and insights on how filter dryers can significantly unlock efficiency in compressor operations, ensuring both productivity and cost-effectiveness in various industrial settings.

The efficiency of compressors in various industrial applications is significantly influenced by the performance of filter dryers. These components play a critical role in maintaining the air quality necessary for optimal compressor operation. According to industry reports, air contamination can decrease compressor efficiency by up to 25%, illustrating the crucial impact of effective filtration. By removing moisture, dirt, and other particulates from compressed air systems, filter dryers help ensure that compressors work under ideal conditions, leading to enhanced performance and reduced operational costs.

Incorporating filter dryers not only safeguards connected vehicle systems from contamination but also boosts the overall efficiency metrics of compressors. Studies indicate that, when used correctly, filter dryers can improve energy efficiency by as much as 15%. Furthermore, maintaining clean air systems can prevent costly downtime and service interruptions that may arise from system failures due to contaminants. The adoption of quality filter dryers is therefore essential for industries aiming to optimize performance and reliability in their compressor systems.

This bar chart illustrates the significant improvement in compressor efficiency with the installation of filter dryers. The data showcases a rise from 75% efficiency before installation to an impressive 90% after implementation, highlighting the essential role of filter dryers in enhancing compressor performance.

Moisture control is critical for the optimal performance and longevity of compressors. Excess moisture can lead to a range of issues, including rust, corrosion, and reduced efficiency, ultimately shortening the lifespan of compressor systems.

Filter dryers play an essential role in moisture removal by ensuring that compressed air or gas remains free from contaminants that could cause failures. By effectively eliminating moisture, filter dryers help maintain the integrity of the compressor components and ensure smooth operation.

Moisture control is critical for the optimal performance and longevity of compressors. Excess moisture can lead to a range of issues, including rust, corrosion, and reduced efficiency, ultimately shortening the lifespan of compressor systems.

Filter dryers play an essential role in moisture removal by ensuring that compressed air or gas remains free from contaminants that could cause failures. By effectively eliminating moisture, filter dryers help maintain the integrity of the compressor components and ensure smooth operation.

The correlation between moisture removal and compressor longevity cannot be overstated. Effective moisture management not only enhances performance but also reduces energy costs associated with increased wear and tear on compressor systems. When moisture is consistently removed from the compressed air, manufacturers can achieve stable operating conditions that enhance both reliability and efficiency. By integrating high-quality filter dryers into compressor setups, facilities can significantly extend the operational lifespan of their equipment while minimizing downtime and maintenance costs. Thus, investing in effective moisture control technology is crucial for any organization aiming to optimize their compressor performance and longevity.

Filter dryers play a pivotal role in enhancing compressor performance by ensuring that the compressed air is free from contaminants and moisture. The significance of adhering to optimal specifications cannot be overstated, as these standards directly influence the efficiency, reliability, and longevity of the compressor system. Key specifications include the filtration efficiency, moisture retention capacity, and pressure drop characteristics, which all contribute to maintaining seamless operations and reducing downtime.

Tips for selecting the right filter dryer include evaluating your specific application needs, considering the operating pressure and flow rate, and ensuring compatibility with existing equipment. Additionally, regular maintenance is crucial to sustain performance—this means checking and replacing filter elements as recommended by the manufacturer. Investing in high-quality filter dryers that meet industry standards not only minimizes the risk of costly breakdowns but also enhances the overall operational efficiency of your systems.

When choosing a filter dryer, look for models that offer advanced features such as automatic drain functions and real-time monitoring capabilities. This technology can further improve system performance by ensuring optimal moisture control and operational readiness, ultimately leading to significant cost savings over time.

The implementation of advanced filter dryer systems plays a crucial role in enhancing the performance of compressors, as highlighted by recent case studies. These systems are designed to eliminate moisture and particulates from compressed air, which not only extends the lifespan of the equipment but also significantly boosts operational efficiency. In industries where precision and reliability are paramount, such as pharmaceuticals and food processing, adopting filter dryers has resulted in measurable improvements in product quality and consistency.

Real-world examples illustrate the tangible benefits of integrating filter dryers into existing systems. One case study showcased a manufacturing facility that experienced a remarkable reduction in maintenance costs after implementing a sophisticated filter dryer solution. The system's ability to maintain optimal humidity levels led to fewer compressor failures and minimized downtime, allowing the company to enhance productivity. Furthermore, the technological advancement in filter dryer systems mirrors the developments seen in other fields, such as the growing application of robotics in geriatric rehabilitation, where efficiency gains are also driving innovation and improved outcomes.

In the realm of industrial efficiency, filter dryers play an essential role in optimizing compressor performance, leading to significant cost savings in maintenance. As the market for compressed air treatment equipment is expected to exceed $9.3 billion in 2024, driven by industrial growth and increasing regulations regarding energy efficiency and pollution control, the importance of efficient compressor operation cannot be overstated. Filter dryers not only enhance the reliability of compressors but also reduce the overhead costs associated with maintenance and repairs.

With a projected compound annual growth rate of 7.4% from 2025 to 2034, the demand for advanced filtration systems will only increase as industries strive to meet stricter environmental standards. By integrating filter dryers into their compressor systems, companies can achieve better operational efficiency and lower energy consumption, thereby quantifying significant cost savings. As industries navigate the complex landscape of chemical processing equipment, the incorporation of effective filtration and drying solutions represents a strategic investment towards enhanced performance and sustainability.